Solar panels are the heart of any photovoltaic (PV) system. They’re what convert sunlight into electricity, and their design, material, and configuration all influence how much energy your system can produce.

At a technical level, solar panels are made of smaller units called solar cells, connected together in a grid and laminated into a weatherproof structure. When multiple panels are wired together, they form a solar array.

Commercial installations today use a range of technologies, but the most common panel types fall into two categories:

- Cell Type – the kind of solar cell used (Monocrystalline, Polycrystalline, or Thin Film)

- Panel Type – the physical design of the panel (Monofacial or Bifacial)

Understanding both helps determine the best panel for your site, budget, and performance goals.

Solar Cell Types: What’s Inside the Panel?

Cell Type: Monocrystalline Cells #

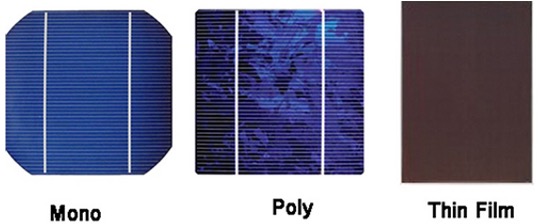

Monocrystalline (or “mono”) cells are made from a single, high-purity silicon crystal. These are the most efficient and widely used solar cells in commercial systems today.

- Sleek black appearance

- Efficiency: 17–22%

- Higher power output per square foot

- Performs better in low-light conditions

- Often more expensive per watt, but worth it for space-constrained rooftops

Cell Type: Polycrystalline Cells #

Polycrystalline (“poly”) cells are made from multiple fragments of silicon melted together. Once the dominant type in earlier solar applications, they’ve been largely phased out of modern commercial use.

- Bluish hue with visible crystal grain

- Efficiency: 15–17%

- Lower cost per watt, but larger area needed for same output

- Less aesthetic and less efficient than mono cells

- Rarely used in new commercial projects today

Cell Type: Thin-Film Cells #

Thin-film panels use a completely different manufacturing process, applying a thin layer of photovoltaic material (like cadmium telluride or CIGS) onto glass or metal.

- Low profile, lightweight, and sometimes flexible

- Efficiency: Historically 11–14%

- Best suited for niche or specialty applications (e.g., low-weight roofs, curved surfaces)

- Large area required for equivalent output

- Not commonly used in standard commercial installations, but improving rapidly

Panel Designs: How They Capture Light

Panel Type: Monofacial Panels #

These traditional panels produce power only from the front side. They feature a white polymer backing that reflects light back through the cells for maximum front-side efficiency.

- Still the most widely used panel type

- Ideal for roof-mounted systems or anywhere the back side has limited light exposure

- Often slightly more cost-effective than bifacial models

Panel Type: Bifacial Panels #

Bifacial panels capture sunlight from both the front and back. Their rear side is made of clear glass or transparent polymer, allowing indirect or reflected light to pass through and activate the back side of the cells.

- Slightly higher overall production (~5–15% gain in ideal conditions)

- Commonly used in ground-mounted or canopy systems where reflected light is available

- Lower annual degradation and often longer warranties

- Performance varies by site conditions (e.g., surface reflectivity)

Quick Comparison: Cell & Panel Types

| Feature | Monocrystalline | Polycrystalline | Thin-Film | Monofacial | Bifacial |

| Cell Material | Single crystal silicon | Multi-crystal silicon | PV material on substrate | Crystalline | Crystalline |

| Efficiency Range | 17–22% | 15–17% | ~11–19% | Matches cell type | 105–115% of front side |

| Visual Appearance | Black, uniform | Blue, grainy | Matte or dark | Solid backsheet | Transparent back or glass |

| Typical Use | Most commercial projects | Rare today | Specialty cases | Most rooftops | Canopies, ground mounts |

| Cost per Watt | Moderate to High | Low (legacy) | Low to Moderate | Slightly lower | Slightly higher |

| Durability/Warranty | 25–30 years | 25 years | 20–25 years | 25–30 years | Often longer |

Power Output & Cell Count

Modern commercial solar panels typically include 144 half-cut cells and produce between 400W–550W. Ground-mounted systems are increasingly moving toward larger panel formats (e.g., 540–550W) to reduce balance-of-system costs and optimize installation labor. For non-commercial/non-utility scale systems, panels are generally smaller (300–400W with 60 or 72 cells).

Recent jumps in power output are due not to major breakthroughs in efficiency, but to increases in physical panel and cell size, a sign of a maturing industry optimizing for scale.

Want to understand how panels connect and convert power?

Learn about Section 3.1.2: Inverters and Section 3.1.3: Balance of System (BOS)

Curious about how these panels are physically installed?

Explore mounting options in Sections 3.1.4 – 3.1.5 – 3.1.6